| 350 MW余热锅炉变工况运行特性分析 |

| |

| 引用本文: | 卢培, 李小宝, 郑晨旭, 邹璐垚, 王欣瑶, 蒋佳月, 胡鋆, 周兴. 350 MW余热锅炉变工况运行特性分析[J]. 南方能源建设, 2022, 9(3): 41-49. doi: 10.16516/j.gedi.issn2095-8676.2022.03.005 |

| |

| 作者姓名: | 卢培 李小宝 郑晨旭 邹璐垚 王欣瑶 蒋佳月 胡鋆 周兴 |

| |

| 作者单位: | 1.河北师范大学 中燃工学院, 河北 石家庄 050024;;2.河北师范大学 化学与材料科学学院, 河北省无机纳米材料重点实验室, 河北 石家庄 050024 |

| |

| 基金项目: | 河北省高等学校科学技术研究(QN2021091,QN2021090);河北师范大学博士基金(L2021B35,Ll2021034) |

| |

| 摘 要: |

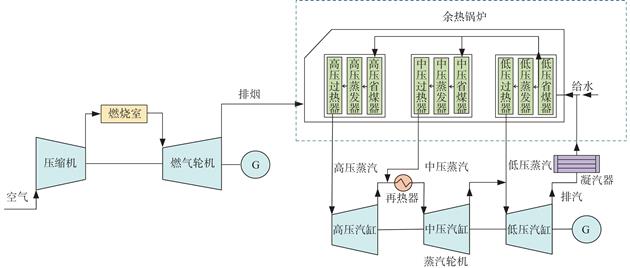

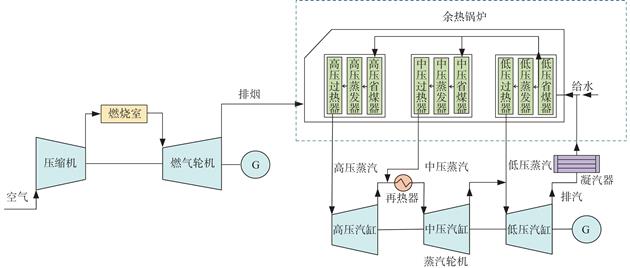

目的 整体煤气化联合循环(IGCC)发电技术是高效、低碳的发电技术,余热锅炉是IGCC的组件之一。文章旨在研究余热锅炉变工况运行特性以提高整体煤气化联合循环发电技术的效率。 方法 通过分析余热锅炉的工作原理及传热传质原理,使用MATLAB软件展开编程计算,探究给水温度、给水压力、液相换热系数以及气相换热系数与余热锅炉内吸热量的关系。 结果 结果发现,当液相换热系数在200~1 000 W/(m2·K)和气相换热系数在20~100 W/(m2·K)范围内时,如果给水温度从30 ℃增加到100 ℃或给水压力增加,余热锅炉的吸热量将不断减少。反之,假设给水温度在30~100 ℃范围内,当液相换热系数从200 W/(m2·K)增加到1 000 W/(m2·K)或气相换热系数从20 W/(m2·K)增加到100 W/(m2·K)时,余热锅炉的吸热量不断增加。 结论 在液相换热系数与气相换热系数不变的情况下,给水温度或给水压力增加,余热锅炉的吸热量会减少;在给水温度与给水压力不变时,液相换热系数或气相换热系数增加,余热锅炉的吸热量会增加。

|

| 关 键 词: | 整体煤气化联合循环 余热锅炉 变工况运行 350 MW 运行特性 |

| 收稿时间: | 2022-05-21 |

| 修稿时间: | 2022-06-20 |

|

| 点击此处可从《南方能源建设》浏览原始摘要信息 |

|

点击此处可从《南方能源建设》下载全文 |

|