| 动态载荷下奥氏体不锈钢管道LBB环向贯穿裂纹稳定性实验及理论分析方法研究 |

| |

| 引用本文: | 何风, 姚迪, 王新军, 李一磊, 白晓明, 熊夫睿. 动态载荷下奥氏体不锈钢管道LBB环向贯穿裂纹稳定性实验及理论分析方法研究[J]. 核动力工程, 2022, 43(2): 133-137. doi: 10.13832/j.jnpe.2022.02.0133 |

| |

| 作者姓名: | 何风 姚迪 王新军 李一磊 白晓明 熊夫睿 |

| |

| 作者单位: | 1.中国核动力研究设计院核反应堆系统设计技术重点实验室,成都,610213;;2.中国核动力研究设计院反应堆工程研究所,成都,610213 |

| |

| 摘 要: |

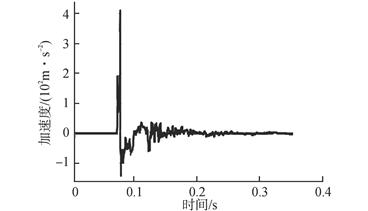

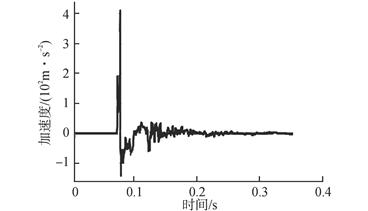

管道环向贯穿裂纹是否稳定是评判管道是否满足破前漏(LBB)设计准则的标准之一,为确保LBB技术安全可靠,对管道环向贯穿裂纹在动态载荷下的稳定性进行实验研究。采用水平冲击机对含环向贯穿裂纹的管道依次进行加载速度为1.22、2、3、4 m/s的高温不带运行压力的冲击实验,以获得各应变率下的实验极限载荷值,并与工程理论分析计算结果进行比较。

分析表明:奥氏体不锈钢管道环向贯穿裂纹在动态载荷下的失效模式为塑性失稳;经实验验证,在工程中对承受动态载荷的奥氏体不锈钢管道进行LBB分析时,采用美国核管会标准审查大纲3.6.3破前漏评估程序(SRP 3.6.3)中的极限载荷理论分析方法具有较高的工程安全性,若同时选用准静态下的材料力学性能,则工程安全性更高。

|

| 关 键 词: | 奥氏体不锈钢管道 环向贯穿裂纹 裂纹稳定性 动态载荷 冲击实验 极限载荷 |

| 收稿时间: | 2021-07-20 |

| 修稿时间: | 2021-08-05 |

|

| 点击此处可从《核动力工程》浏览原始摘要信息 |

|

点击此处可从《核动力工程》下载免费的PDF全文 |

|