| 窄矩形通道污垢沉积数值仿真 |

| |

| 引用本文: | 谭佳琦, 刘达霖, 刘晓晶. 窄矩形通道污垢沉积数值仿真[J]. 核动力工程, 2022, 43(5): 76-81. doi: 10.13832/j.jnpe.2022.05.0076 |

| |

| 作者姓名: | 谭佳琦 刘达霖 刘晓晶 |

| |

| 作者单位: | 上海交通大学核科学与工程学院,上海,200240 |

| |

| 基金项目: | 国家自然科学基金(11922505); |

| |

| 摘 要: |

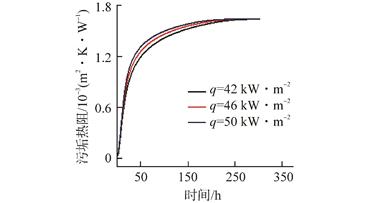

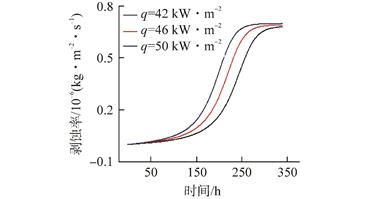

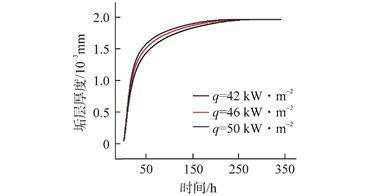

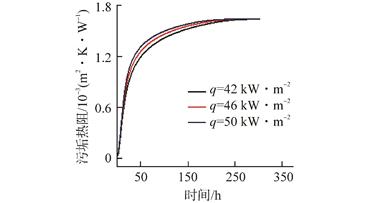

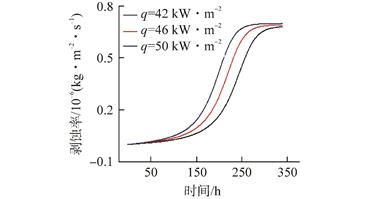

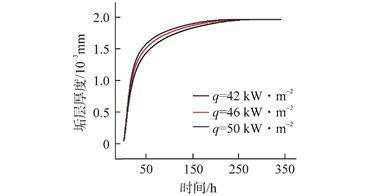

为研究窄矩形通道内CaSO4溶液由于析晶沉积产生的污垢及对换热的影响,本研究基于合理的污垢沉积、污垢剥蚀与污垢热阻模型,利用FLUENT软件结合用户自定义函数(UDF)对一定热流密度、入口流速、入口温度和流体浓度的流体进行了析晶沉积模拟计算。研究结果表明了此工质的污垢产生情况和对换热的影响,同时得到热流密度、入口流速和流体浓度3种影响因素对污垢沉积的影响:污垢热阻随热流密度增大而增大,随入口流速增大而减小,随流体浓度增大而增大。

本研究可用于模拟板状燃料元件窄矩形通道由于析晶导致的污垢沉积过程。

|

| 关 键 词: | 窄矩形通道 析晶沉积 FLUENT 污垢沉积 污垢剥蚀 污垢热阻 |

| 收稿时间: | 2021-10-19 |

| 修稿时间: | 2021-11-10 |

|

| 点击此处可从《核动力工程》浏览原始摘要信息 |

|

点击此处可从《核动力工程》下载免费的PDF全文 |

|