| 高产抗菌脂肽芽孢杆菌的分离鉴定筛选及发酵工艺优化 |

| |

| 引用本文: | 纪帅奇,乌日娜,张淘崴,等. 高产抗菌脂肽芽孢杆菌的分离鉴定筛选及发酵工艺优化[J]. 食品工业科技,2024,45(4):101−108. doi: 10.13386/j.issn1002-0306.2023040051. |

| |

| 作者姓名: | 纪帅奇 乌日娜 张淘崴 娄梦雪 贺凯茹 张妍 武俊瑞 |

| |

| 作者单位: | 1.沈阳农业大学食品学院,辽宁沈阳 110866;2.辽宁省食品发酵技术工程研究中心,辽宁沈阳 110866;3.沈阳市微生物发酵技术创新重点实验室,辽宁沈阳 110866 |

| |

| 基金项目: | 国家自然科学基金面上项目(32172279);沈阳市科技创新平台项目(21-103-0-14,21-104-0-28)。 |

| |

| 摘 要: |

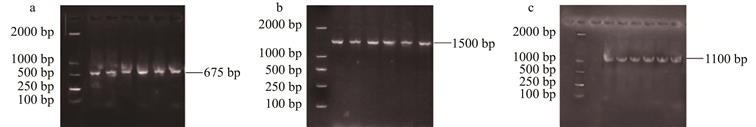

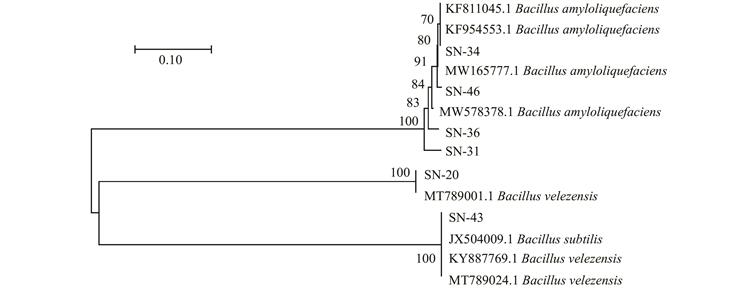

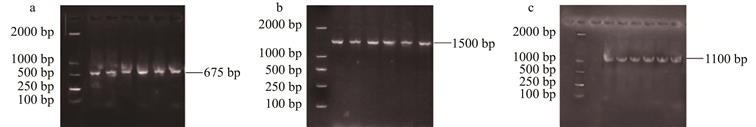

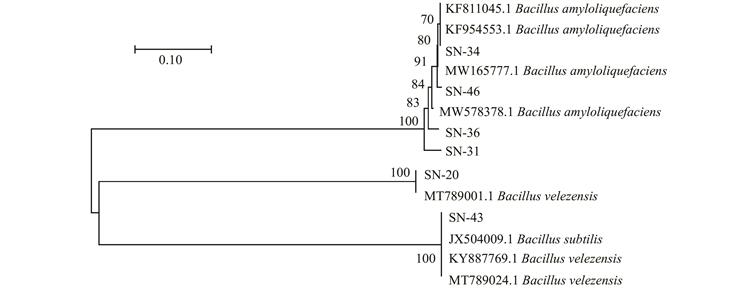

为了筛选出高产抗菌脂肽的芽孢杆菌并确定其最佳发酵工艺条件,研究从传统发酵豆酱中分离和鉴定产抗菌脂肽芽孢杆菌菌株,通过正交试验研究了发酵接种量、发酵填液量、发酵时间、发酵温度等发酵条件对芽孢杆菌脂肽产量的影响。结果表明,从9份东北传统发酵豆酱中分离筛选得到27株芽孢杆菌,经16S rDNA鉴定,其中6株芽孢杆菌具有合成脂肽的基因sfp、fenB和ituA。通过单位菌体脂肽产量和抑菌效果测定发现,贝莱斯芽孢杆菌SN-20和解淀粉芽孢杆菌SN-46表现优异,单位菌体脂肽产量达106和72 mg,且对革兰氏阳性和阴性指示菌均有较强的抑菌效果。

正交试验发现贝莱斯芽孢杆菌SN-20最佳发酵工艺为:接种量3%,发酵填液量20%,发酵时间36 h,发酵温度32 ℃;枯草芽孢杆菌SN-46最佳发酵工艺为:接种量2%,发酵填液量40%,发酵时间24 h,发酵温度32 ℃。在此条件下发酵的两株芽孢杆菌单位菌体脂肽产量优化前为106.11和76.23 mg/g,优化后分别提高了21.85%和23.84%。研究结果有效地增加了芽孢杆菌抗菌脂肽的产量。

|

| 关 键 词: | 抗菌脂肽 芽孢杆菌 筛选 鉴定 发酵工艺优化 |

| 收稿时间: | 2023-04-07 |

|

| 点击此处可从《食品工业科技》浏览原始摘要信息 |

|

点击此处可从《食品工业科技》下载免费的PDF全文 |

|