| TiBw/TA15钛基复合材料真空钎焊界面组织及性能研究 |

| |

| 引用本文: | 叶嘉宝, 李晓红, 邓云华, 谢志怡, 文彦臻. TiBw/TA15钛基复合材料真空钎焊界面组织及性能研究[J]. 焊接学报, 2023, 44(6): 111-119. DOI: 10.12073/j.hjxb.20220811001 |

| |

| 作者姓名: | 叶嘉宝 李晓红 邓云华 谢志怡 文彦臻 |

| |

| 作者单位: | 中国航空制造技术研究院 航空焊接与连接技术航空科技重点实验室, 北京, 100024 |

| |

| 摘 要: |

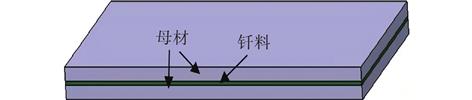

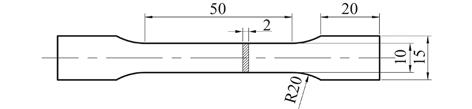

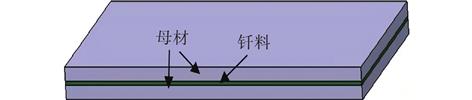

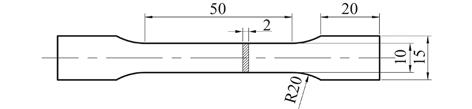

采用Ti-Zr-Cu-Ni钎料对TiBw/TA15钛基复合材料进行真空钎焊,对不同工艺参数下钎焊接头组织及性能进行分析. 结果表明,钎焊界面主要由针状的α-Ti相、间隙β-Ti相及Ti2(Cu,Ni)金属间化合物及TiBw增强相组成. 随着钎焊温度(920 ~ 980 ℃)和保温时间(60 ~ 150 min)的增加,针状α-Ti相占比增加,金属间化合物减少,TiBw分布趋于均匀,接头力学性能增加.

但较长的保温时间导致界面宽度增加,使接头整体塑性下降. 钎料添加量较少且适宜的情况下,钎焊温度980 ℃,保温时间90 min下能获得最佳力学性能.

|

| 关 键 词: | 钛基复合材料 真空钎焊 钎焊接头 界面组织 工艺参数 |

| 收稿时间: | 2022-08-11 |

|

| 点击此处可从《焊接学报》浏览原始摘要信息 |

|

点击此处可从《焊接学报》下载免费的PDF全文 |

|